Revolutionizing Feed Monitoring with BinTalk

June 23, 2023 | Blog

Maddy McGarry

Product Marketing Manager

Climbing up and down your feed bin ladders? Tapping the sides of your bins to guess how full they are? If not tedious and cumbersome, the old ways of measuring feed are risky and dangerous. These shared frustrations among growers led BarnTools to create BinTalk, a wireless feed bin sensor that is reliable and accurate, easy to install, and affordable to adopt.

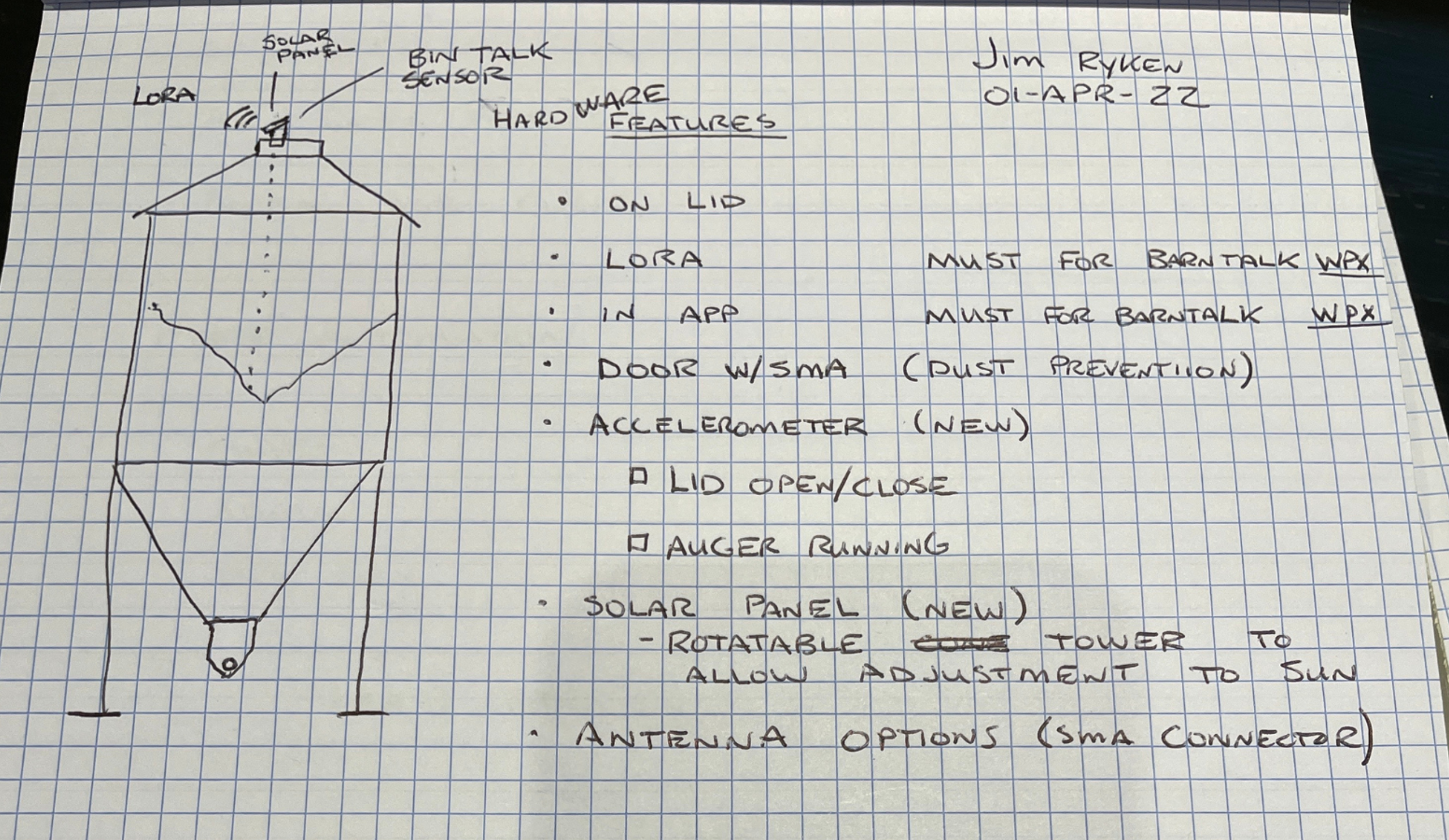

From Day 1, BarnTools’ mission to create an all-around wireless feed monitoring system has been solution-driven. “There was a lot of research done on what the right technology was, how to mount the feed sensor, and how to come up with the right power supply,” said BarnTools COO and Co-Founder Jim Ryken, who helped spearhead the development of BinTalk.

With many existing feed monitoring products, growers are required to drill holes in their bins to install them.

“We wanted BinTalk to take 10 minutes to install and not require you to compromise the integrity of the bin from drilling holes or creating a water leak path.”

BinTalk is installed on the top of the feed bin using patented clip-on mounting and measures feed volume using HD camera technology. Every six hours, the camera takes a picture and receives a point cloud — data points that represents an object or space — showing the amount of feed in the bin.

Jim says the team worked with a vision engineer to develop an algorithm that converts a point cloud image into volume. Using edge computing, the camera calculates the volume of feed in the bin and sends it to the cloud.

“Our camera clips on the bin, magnetically sticks to the bin, and then we close the lid so we control the lightning.

There is probably not a more accurate use of a camera. The variables you’d normally have to deal with aren’t there. The camera doesn’t move, and it’s always dark inside the bin.”

BinTalk’s accuracy was proven at test farms where it was placed on top of 20 bins with load cells. Compared to the bin scales, BinTalk yielded 96% accuracy in measuring feed volume. The accuracy increases even further when the bin is less than 50% full.

Unlike other feed monitoring systems, Jim says they do not need to collect bin dimensions or specs from customers in order to capture feed volume. The BinTalk sensor is self-calibrating: Once the feed bin is emptied the first time, that will establish the capacity for all future calculations. “We can take a picture of the empty bin and know the volume. That becomes the capacity of the bin.”

“Other sensors send an entire picture to the cloud and have to process the picture in the cloud, and the cloud estimates back how much feed is in the bin,” Jim said. “You have to pay $30-40 per bin to access those images, and if you don’t have internet on your site, it's not going to work.”

The extensive research and testing conducted by Jim and the team is equipping growers, producers, and integrators with a feed monitoring solution that will help them streamline their feed management practices and avoid costly feed outages.

Connect with an Expert

Related Resources

Wireless Feed Bin Sensors for Swine and Poultry

Wireless feed bin sensors have been developed to help growers measure the amount of feed in their bins, helping to optimize feed delivery schedules, reduce out of feed events, and improve their animals’ performance.

The Advantages of Using Wireless Feed Bin Sensors for Efficient Production

For pig and poultry growers, wireless feed bin sensors are a reliable solution that offers several benefits over traditional methods of measuring feed.